We provide full transparency in pricing structure

Cost

Management of cost is seen by AMS as a crucial business enabler for our clients and a service proposition for AMS. We achieve efficiency through constant attention to several key factors; low overhead, lean organization, keeping expert knowledge close to the client and early Design for Manufacturing analysis. Our many years of experience in local supply chain management in China, with feet on the ground in the worlds’ manufacturing center, result in delivery of the client’s product within the agreed budget.

We use an industry standard manufacturer’s mark up as gross margin on materials cost for the assembled product. No additions on consigned parts. An open book Bill of Materials and applied margins provide full transparency in pricing structure and builds trust between AMS and our clients.

We have an extremely low defect rate (< 1%) on our assembled products. The low scrap rate in production is achieved through strict supplier quality control combined with first pass qualification of parts production runs. We report on this as an internal KPI.

Services are charged at competitive hourly rates and will vary depending on the location of the activity (NL or China).

Quality

AMS holds both ISO 9001 and ISO14001 certifications and was recently award the status of China High-Tech company by the Province of GuangDong.

AMS selects its suppliers not only on price and lead time but also on capability and fit. This allows us to select the right partner for the right job and maintain our quality levels.

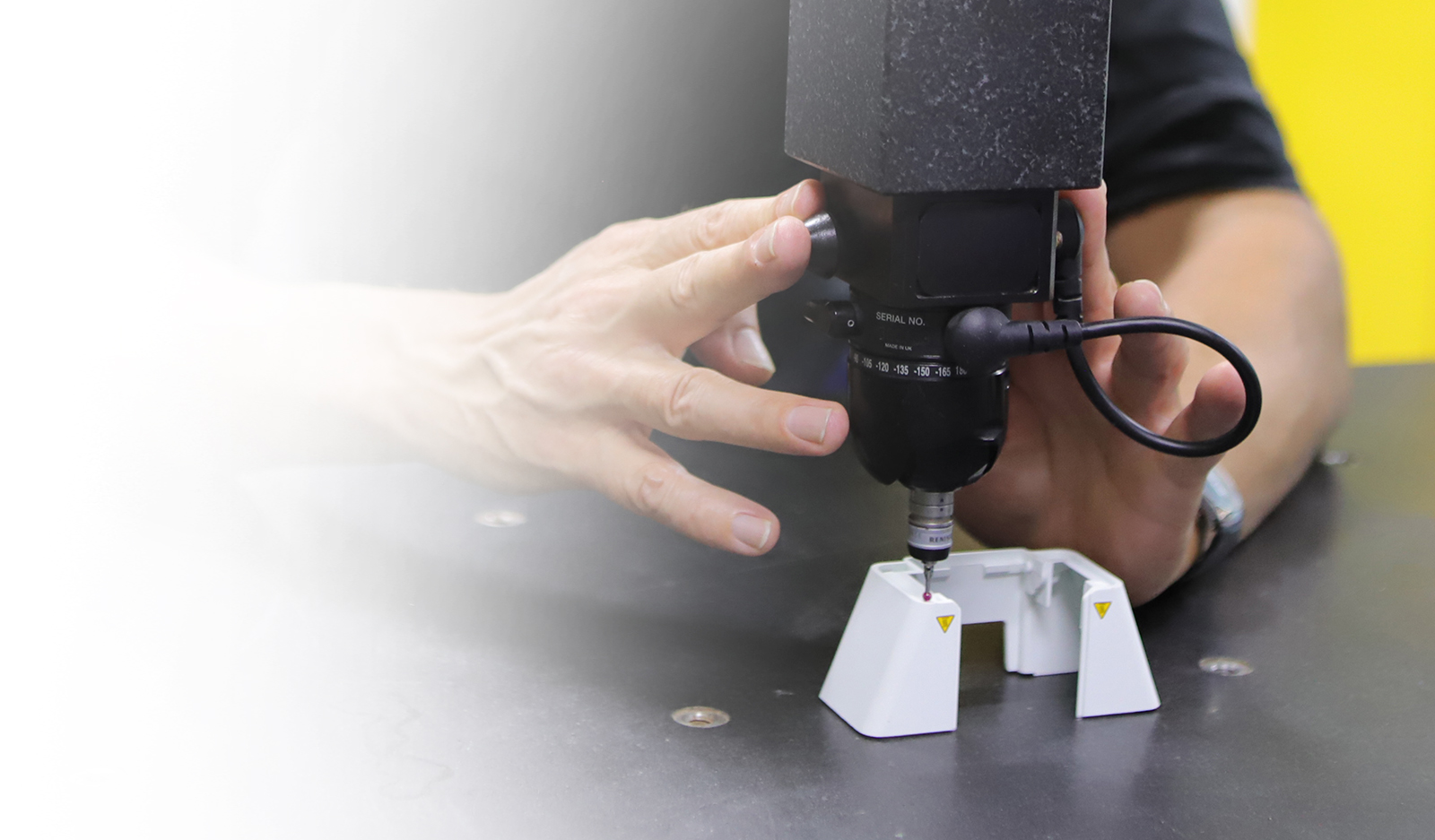

Our dedicated tooling team takes care of mould quality assurance and process assurance. Our moulding suppliers are monitored based on process capability statistics (Cp-Cpk). New products follow a stage gated project template that is evidence based, rather than task based. Our process driven organization uses many of the proven methodologies found in much larger companies such as Toyota and Philips.

AMS Group awarded the status of China High-Tech company

Dedicated planning & on-time delivery

Schedule

The agreed product at the right price AND at the agreed time. Schedule is the third, but certainly not the lowest priority managed by

AMS. Our experienced and dedicated planning and logistics team have close contact with both our clients and suppliers to ensure on-time delivery.

AMS expert knowledge of the selected manufacturing processes allows for accurate and predictable lead times. Communication takes place locally in native languages and inter-site in English avoiding difficult language barriers and misunderstanding.

4 value streams

4 value streams

NPD

New Product Development, from concept to mass manufacturing.

NPI

New Product Introduction, “build to print” of a client designed & engineered product.

Repeat orders

Through smart sourcing and process improvement we aim to increase efficiency and cost effectiveness.

Export tooling

AMS commissions and delivers Injection Moulding tooling (moulds) to clients for component manufacture in Europe. We have delivered over 2000 moulds since we began in 2003.